Planting season has returned! To celebrate we have compiled a list of planting tips and reminders to help get you and your Kinze planter primed for action.

1. Graphite Done Right

Standard Hoppers: Once the hoppers are full, take your bottle of graphite and make a good line around the edge of the hopper.

Bulk-Fill: We recommend using at least 1 – 2 lbs. of graphite per 50 units of seed, which can be layered in as you fill the hoppers.

Tip: To verify you are using enough graphite, open the meter and rub your fingers over the disc, backing plate, housing etc. They should be black from graphite use. If not, add more graphite.

2. Let’s Talk Talc

Talc powder is recommend for use when seed has a sticky or tacky treatment.

Tip: Stick your hand in the seed, make a fist and then remove it. If seed sticks to your hand, you need talc.

Talc needs to be mixed in completely as it does not sift through the seed like graphite. Even if talc is required, the full rate of graphite should still be added to ensure proper lubrication for meters.

3. Setting Down Pressure

A number of variables influence correct down pressure settings, including soil type, field conditions and planting speed.

Tip: Set the planter down, pull forward in the field and stop. Leave the planter in the ground and go back and kick the gauge wheel tires. If the gauge wheels free wheel, more down pressure is needed. If they don’t move at all, reduce down pressure.

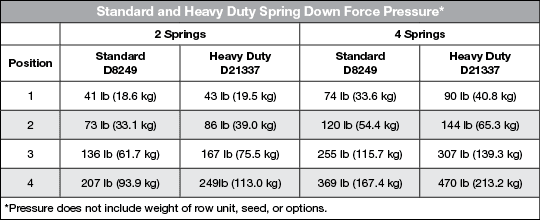

Spring down pressure reference settings:

Tip: Once you make a pass, check behind the row units and make sure you can see the entire gauge wheel imprint in the ground to ensure you have enough down pressure.

4. A Closer Look at Closing Wheels

You will want to make sure the closing wheels are centered over the trench. This can be verified in the field at the same time you are setting the down pressure.

Tip: Place the planter in the ground, drive ahead and stop with the planter in the ground. Go back behind the planter and inspect the closing wheel V and make sure it is centered. If adjustment is needed, there are eccentric bushings near the closing wheel pivots that allow adjustment and centering of the wheel with the seed trench.

5. Know Your Row Cleaners

Residue in the seed trench can affect emergence. Row cleaners move residue through to ensure smooth row unit operation.

Tip: Properly set row cleaners move about one-half to two-thirds of the time — or just barely skim across the ground. Occasionally look back while going across the field to make sure the residue wheels are not turning all the time.

Reminder: Row cleaners should not be used to move dirt or be set deep enough to cause valleys in the field. During heavy rains water will run down those valleys, which could potentially wash out the seed in the trench.

6. Hitch and Toolbar Height

Proper hitch and toolbar height are paramount to accurate planting. Here are some tips to make sure you stay on the level.

- When in the planting position, ensure the hitch of the planter is level to running slightly up-hill to the tractor.

- Make sure your toolbar is level to slightly up-hill as well and adjust with hitch or wheel locations.

- Make sure the height of your toolbar is 20-22 inches (23-25 inches on a 4900 planter) from the ground.

- Make sure parallel arms are approximately parallel to the ground when in the planting position and level accordingly with aforementioned adjustments.

- Always check toolbar height and levelness in the field fully loaded to ensure proper adjustment.

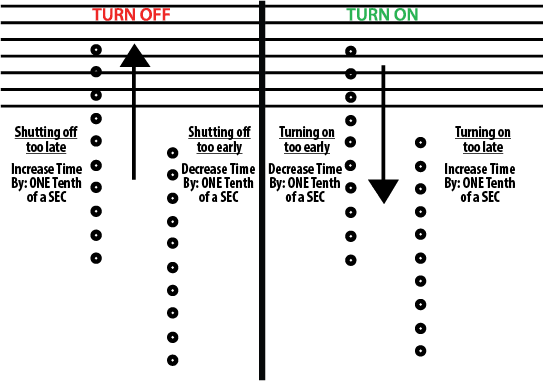

7. Clutch Shut-off Performance

Timing is everything here and this graphic offers some helpful reminders for getting it just right.Hopefully these tips come in handy this planting season!