In Kinze News

Why Upgrade to Vacuum Seed Meters?

It’s that time of year again to make last minute decisions and preparations for the 2019 planting season. Throughout the winter you have been to clinics, seminars, and blasted with ads on social media — all with the message to be more efficient and profitable. So now what? Optimally, the lowest cost investment with the highest and quickest return is the most appealing, right? Have you considered updating your mechanical meters to vacuum meters? Performance Why vacuum meters? Vacuum metering presents several opportunities over mechanical meters. Performance, cost, and simplicity are all areas where vacuum meters excel over mechanical meter options. Let’s start with performance. Have you ever had an instance where you discovered a hybrid that would excel in a particular field, but steered...

Tips for Planting Season

In just a few weeks, tractors, planters and related equipment will be returning to fields to start planting the 2019 crop. To help you get ready, we have compiled a list of planting tips and reminders to help get you and your Kinze planter primed for action. Even if you have started planting, these tips are still helpful — a small adjustment may have a big impact! Graphite Done Right Standard Hoppers: Once the hoppers are full, take your bottle of graphite and make a good line around the edge of the hopper. Bulk-Fill: We recommend using at least 1—2 pounds of graphite per 50 units of seed, which can be layered in as you fill the hoppers. TIP: To verify you are using enough graphite, open the...

In Kinze News

Christmas Time is Here!

As we wind down 2018 and prepare for the year ahead, may we all be blessed by slowing down and reflecting upon the selfless love of Christ. And may our relationships with family, friends, and others around us be a blessing throughout the coming year. To all our employees who so effectively help us innovate, our dealers who tirelessly promote our products, our customers who honor us with their patronage, and our partners who help us produce our products, we thank you for your dedication, hard work, and support throughout 2018. We look forward to the upcoming year and working with you in bringing new products to farms worldwide! Wishing you a very blessed Christmas Season and a rewarding New Year! ...

In Kinze News

, Mach Till

Spring Tillage Considerations

As winter is slowly starting to loosen its grip, there is talk of a later than normal spring. Are we going to have a shorter window than normal to complete the normal spring work? How much work is still left over from a very challenging fall? Read below how you can put your best practices into place on your farm this spring to get your crop in and growing as soon as conditions are fit. Managing Negative Side Effects and Limiting Potential Damages I had good intentions to complete several tasks this fall, but it would have been a bad decision if I moved forward because the field conditions were not right. I chose to leave the ruts in the...

In Kinze News

What We Are Thankful for This Year

'Tis the season to be thankful for the many blessings bestowed upon us. Watch the video to see what Kinze employees are thankful for this year. From all of us at Kinze, we wish you a very blessed Thanksgiving shared with family and friends! https://youtu.be/AzkMN1r50qs

Kinze Hosts Its First Manufacturing Day Event

This year was our first year hosting a Manufacturing Day event. We were very excited to join the thousands of other manufacturers in "inspiring the next generation of skilled workers." Since 2012, manufacturers across the country have been hosting events for students, parents and instructors to learn more about the diverse career opportunities manufacturing offers. The event was started by the Founding Partner Fabricators and Manufacturers Association, International. In its first year, less than 300 manufacturers hosted an event. Six years later, it’s grown to nearly 3,000 events hosted by manufacturers across the country, including Kinze. “Our goal was to showcase our modern manufacturing facilities and communicate the opportunities we offer high school graduates to innovate, solve problems and earn a good...

In Kinze News

Which Down Force is Right for You?

Why Use Down Force? Every farmer understands when seed is planted it must be placed at a uniform depth, with good seed-to-soil contact, and a consistent seed spacing. In addition, each crop has an optimum depth that promotes the best germination, growth, and yields. For corn this is typically 1.5" to 2" deep, and for soybeans it is 1" to 1.5". To maintain this depth consistently across a field that varies due to compaction, soil type, and residue, a down force system must be properly selected and managed. Before selecting a down force system, it must be emphasized that more is not necessarily better. While having enough downforce to maintain a consistent planting depth is very important to increase yields, having too much down...

In Kinze News

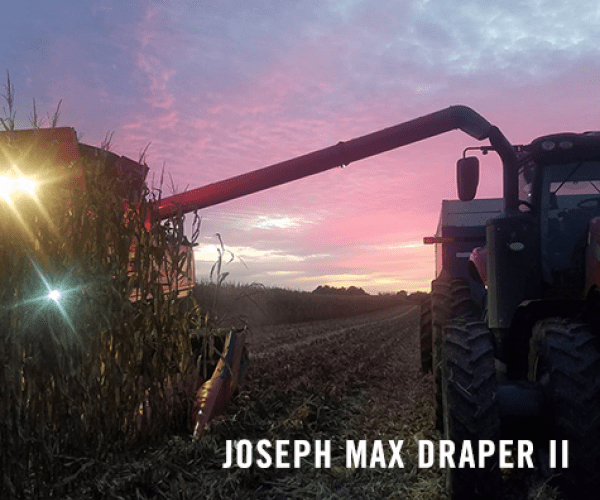

Harvest Update

October 9, 2018 Crop Report Rain. And more Rain. This has been the common theme across the country, making it difficult to get crops out of the field. Despite the struggles a lot of farmers are talking about with weather, the recent USDA Crop Report states that 34 percent of corn has been harvested in primary production states. That is 13 percent more than this time last year. However, soybeans harvested are two percent less than this time last year with 32 percent harvested in primary production states. We, too, are praying for better harvesting and crop conditions. #KINZEHARVEST18 Photos Harvest is one of our favorite times of year. No, not because pumpkin spice EVERYTHING hits the supermarkets, but because we get to see...

In Kinze News

, Mach Till

Fall Mach Till™ Demonstrations

Seeing is believing. That’s why Mach Till hit the road this fall and traveled to several Kinze dealerships across the Midwest to demonstrate its capabilities. It even made a trip to Texas! Area farmers and dealership personnel had the opportunity to operate the machine and experience its performance first-hand. Not only has it traveled to several locations for demos, it’s also traveled to multiple farm shows including Husker Harvest, Dakotafest, Ag Progress Days and Farm Progress Show. Why Till in the Fall? Farmers that plant higher populations, like 36,000, have increased crop residue after harvesting. The more residue on top of the soil, the longer it takes to breakdown throughout the winter. “This tool puts more dirt on top of...

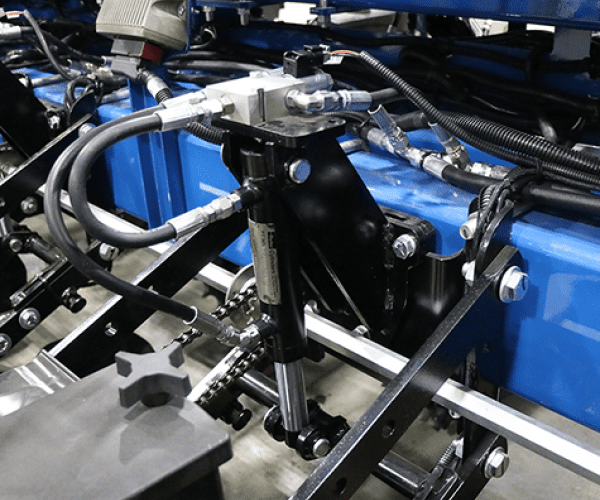

Kinze Hydraulic Weight Transfer

The Problem With Compaction Planters today are bigger than ever — with more rows and increased, centralized seed and fertilizer capacity. While this allows farmers to plant more acres per day and reduce the time needed to fill the planter, there are drawbacks. With so much weight centered above the center rows, pinch row compaction is increasingly becoming a problem that leads to stunted plant growth and reduced yields. Typically, pinch row compaction occurs on the middle six rows next to the transport tires on a bulk fill planter. So, depending on the size of your planter, this can affect anywhere from 50% (12 row planter) to 25% (24 row planter) of the rows in your fields. The differences in yield can be significant...