In Kinze News

Celebrating Five Years in Lithuania!

In May 2013, Kinze announced that it would open a production facility in Vilnius, Lithuania to serve the growing Eastern European planter market. On June 18, 2013, a ribbon cutting and Grand Opening celebration took place at the new facility and the work of setting up the factory began in earnest. By the end of that year, production had started and the first planter rolled off the line. Within three months, production capabilities were increased and over 100 planters were produced. Recently, the fifth anniversary of the Lithuanian facility was celebrated with an event held at the plant in Vilnius. Plant setup and the Grand Opening in 2013 The fifth anniversary celebration took place in the Vilnius production area Fifth anniversary speakers and presentations The 3600...

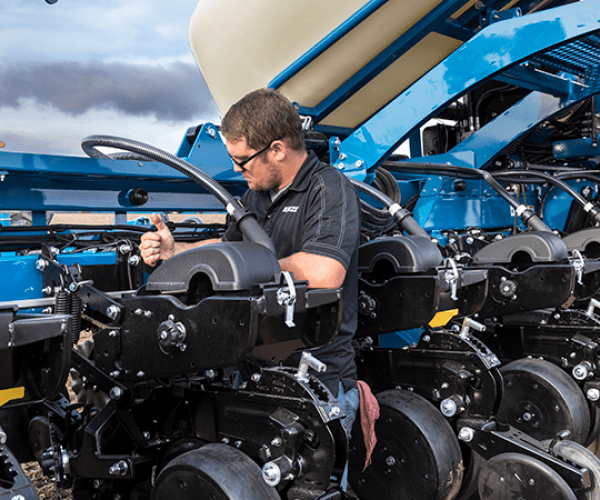

Proto, Tool and Die Department

Ever wonder how the latest Kinze innovations become reality, from idea to final product? Our proto, tool and die department is responsible for bringing new product designs to life. They are a team of fabricators, welders, tooling designers, machinists and assemblers that produce the first test units, and work hand-in-hand with test and design engineers to refine products before the latest technologies like Blue Drive are delivered to you. Not only that, but they also support existing product production by designing and building solutions that improve efficiency, quality and safety. New Product Development A new product idea is approved and the design is ready to go. What’s next? That is where the proto, tool and die team comes in. They create the...

In Kinze News

, Mach Till

Experience Kinze Field Day 2018

On Wednesday, August 2, 2018 many guests attended the Experience Kinze Field Day at Kinze headquarters in Williamsburg, Iowa. The day was organized to provide the attendees an overview of the latest Kinze planter technologies and products along with opportunities to witness field demonstrations and participate in planter test-rides. During the morning presentations, Kinze personnel delivered an overview of the new features for planters for 2019: Blue Vantage. Kinze’s new, easy to use planter display – so simple, that it requires settings be confirmed on only three screens to be ready to plant. Blue Drive. Kinze’s second-generation electric drive system – works seamlessly with the Blue Vantage display to deliver seed exactly where it needs to be. True Depth. Kinze’s...

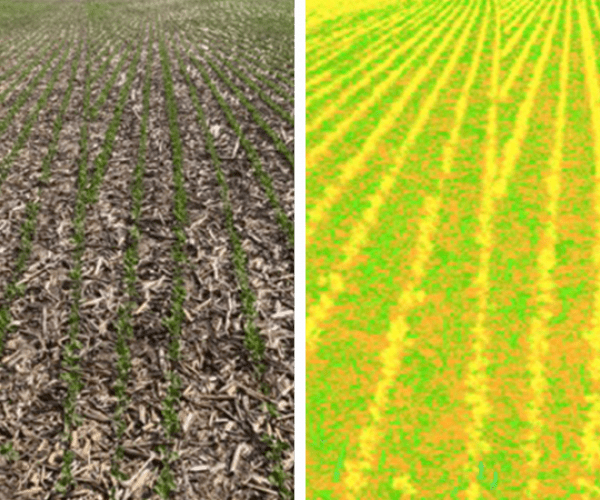

Planter Section Control Technology

In a perfect world, all fields would be square and easily planted. However, that is not the case. You have tree lines, curved terraces, winding roads and waterways to work around. As a planter makes its way towards a waterway, for example, it has to either plant through a waterway or shut off well before a waterway. This can create areas that may be over-planted or under-planted, which can contribute to seed waste or decrease field yield potential. That is where section control technology comes in. Section control technology has been around since the 2000’s. It started with air clutches, and then advanced to electric clutches. Both were chain operated. Fast forward to today, and section control is operated by...

What’s New at the Kinze Innovation Center?

It’s hard to believe that Kinze Innovation Center has been open to the public for over five years! Where has the time gone? We have enjoyed welcoming thousands of visitors of all ages from across the globe and sharing the story of Kinze Manufacturing through interactive displays, videos and full size equipment exhibits. The Kinze Innovation Center was built to give our visitors an experience that goes beyond the products we manufacture, but tells the complete story. How did we become the company we are today? What challenges have we overcome? What do we believe in? Where are we going? Although our mission, vision and core values remain the same, a lot has changed since we first opened the...

Successfully Put Away Your Planter

Spring 2018, in many parts of the country, it was the season that was slow to arrive, and once it got here, the rains would not give a decent break to plant. When it did get fit to plant, the days were long and the sleep was short, but it finally got done. Now the planter is setting in the yard ready to be put away, but with spraying to do and side dressing to get done, its just one of those jobs that takes a back seat to the busyness of everything else. However, don’t put it off too long. Because for your planter to run at peak performance, efficiency and accuracy, what you do now to properly store...

In Kinze News

, Planters

Benefits of Planting With Split Rows

Planting with split rows has been a practice for 40 years. It was originally introduced by Kinze Manufacturing in 1978 as a result of searching for ways to reduce equipment costs. The split row concept is designed to seed conventional (30, 36 or 38 inch rows) and narrow rows (15, 18 or 19 inch rows) with one planter by engaging the push row units. Soybean Narrow Row Spacing Advantages As this practice has grown in popularity, so has the data to support the benefits of 15" soybean row spacing. Increased Profits Based on a 10-year average, planting in 15" rows returned a profit of $31.09/acre more than 30" row widths. See more data here. Increased Yields Soybeans planted in 15" rows average 4.5...

Keeping Planting Simple With Technology

Do you remember when planting was as simple as backing the tractor up to the planter, droping the pin in the hitch and being ready to plant? Technology has made some great advances over the years, but it can be confusing and daunting, and we recognize that. As we researched ways to make technology simpler to use, we surveyed farmers to understand the challenges they had using planting technology. As farmers ourselves, we also experienced some of the same challenges. We started by bringing all planter electronics in house. Using feedback from farmers, our Kinze Electronics team of engineers have worked tirelessly to design new hardware, software and a user interface that works smarter for you. What resulted is the introduction...

In Kinze News

, Mach Till

Mach Till Heads to the Field

Kinze Sales Managers Operate the Mach Till "Easy to hook up, get started, and operate!" "It likes to go fast! The faster you go, the better job it does at sizing and incorporating residue." "When I pulled back the soil, you could see that the Mach Till did not leave a compaction layer like a conventional disc." "Overall an impressive machine that will cover lots of acres with ease." These were just a few of the reactions from Kinze District Sales Managers as they operated the Kinze Mach Till for the first time this week. To see these machines in action, follow the video below. To learn how the Mach Till tillage system works, and how it is different from vertical...

Planting Maintenance Tips

Simple Planter Maintenance Tips for Optimal Performance As you have been patiently waiting to plant, we’ve been sharing planting and planter maintenance tips on our social media channels. We’ve compiled a list of those and added a few more! Even if you have started planting, these tips are still helpful. A small adjustment may have a big impact. Test your meters to ensure you are ready to go and know the vacuum and singulator adjustments before heading to the field. Visit your local Kinze dealer to have your mechanical and vacuum meters tested on the new Kinze T-4000 seed meter test stand.Lubricate your meters. We offer graphite, an 80/20 graphite-talc mix, and standard talc. Make sure your electronics are up to date before...